Our nickel-coated optical fibers have been proven to be suitable for a long time use at high temperatures and are a perfect choice for integration of optical fiber into metal parts. We have developed a method of nickel deposition on optical fibers, which keeps the attenuation low.

Our standard selection of nickel coated optical fibers include:

- 20 μm of Ni on 10 μm of Cu (Monel)

- 60 μm of Ni on 10 μm of Cu

- 120 μm of Ni on 10 μm of Cu

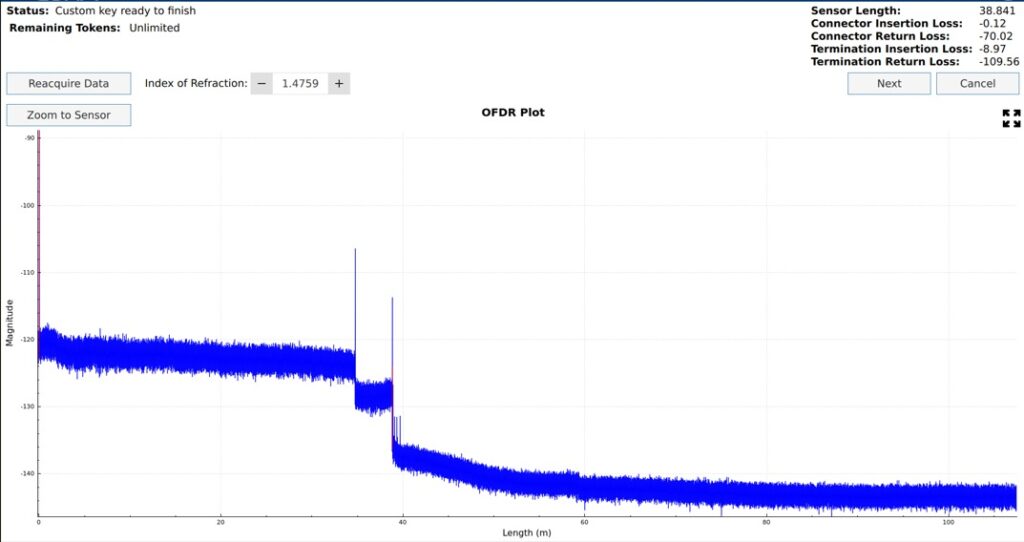

Long life test in metal processing plant proves that our Ni-coated optical fibers can be continuously used at high temperature, while performing distributed OFDR measurements of temperature. Copper and gold are not suitable for such tasks, since after annealing they become soft and do not protect optical fiber from deformations. Silica itself undergoes annealing and becomes very prone to breakage during bending. Read more about this phenomenon on our website.

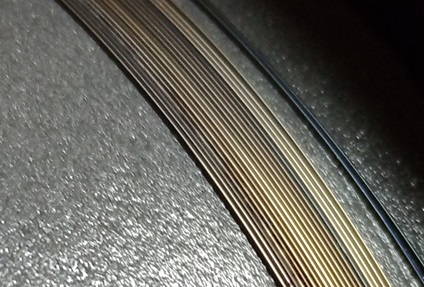

Below you will find cross section of our toughest optical fiber: 120 μm of Ni on 10 μm of Cu, which can operate even at 900°C for 8 months and at 700°C up to a 9 years.

Our standard nickel coating 20 μm of Ni on 10 μm of Cu can withstand up to 20 years at 500°C and up to 2 years at 600°C.

Our nickel coated optical fibers have extremely low attenuation for such a hard coating material. The attenuation may be 20 dB/km or lower, and it is dependent on the coating thickness and the type of the optical fiber.