The question that we hear the most is „Which metal coating will be the best choice for our industrial needs?”. We have carried out years of testing and the conclusions can be found below.

Some customers when talking to us, they directly go to gold coating, since it is well known that gold does not oxidize at high temperatures. However, despite the fact that gold coatings are present on the market for so long, they have not gathered too many positive reviews in the industry. Why is that? Are they just rare, because they are expensive? Or is there some other reason?

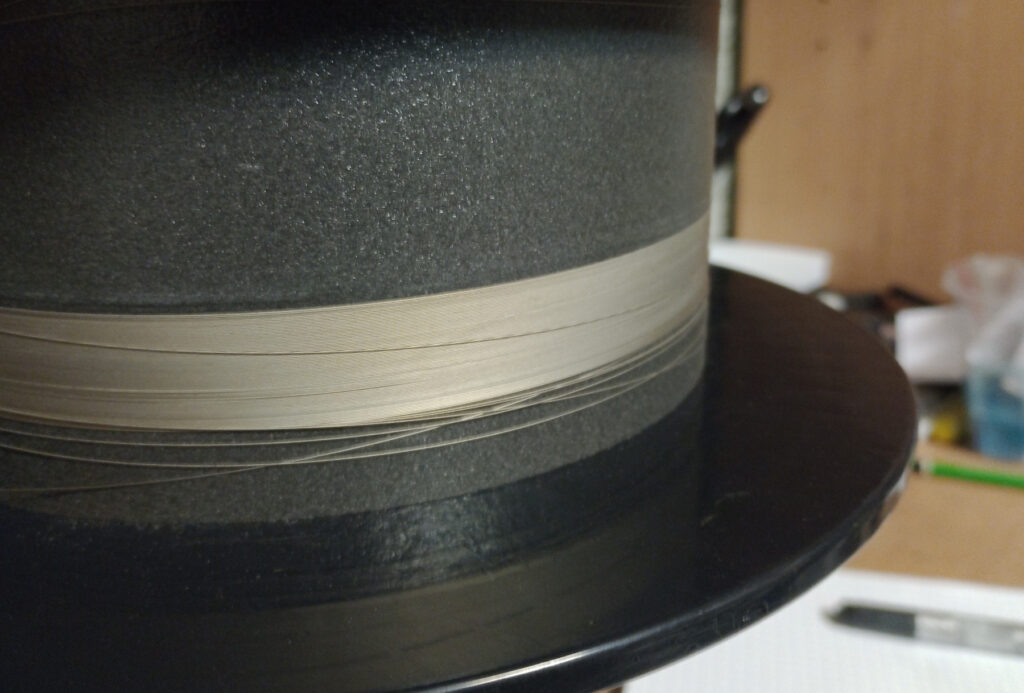

We have placed samples of silica optical fibers (SMF28) with 20-60 µm copper coating in a furnace and we have heated them in air, while slowing down the influx of oxygen to decrease the oxidation rate. Time of annealing was 120 hours (5 days without any breaks) and the temperature was 600°C. After the test most of the coating was already oxidized and since copper oxide does not stick to the copper substrate, it was easy to extract the samples with residue metal coating. Oxidation rate was the same for all the samples and all the samples still had some copper coating all around the fiber. We have measured what would be the minimum bending radius at which samples break. This value was equal to 1 mm for 40 and 60 µm samples and approximately equal to 1.4 mm for 20 µm samples. This means that there was not much difference between this result and the result prior to heating. What was really striking was the behavior of samples during the bending process. Microscope pictures of samples can be found below.

When the fiber which was not annealed is bent, then it forms a U shape, but when an annealed fiber is bent then it forms a V shape. Pictures above prove that inside the coating the fiber is optically damaged and is not suitable to transfer signal.

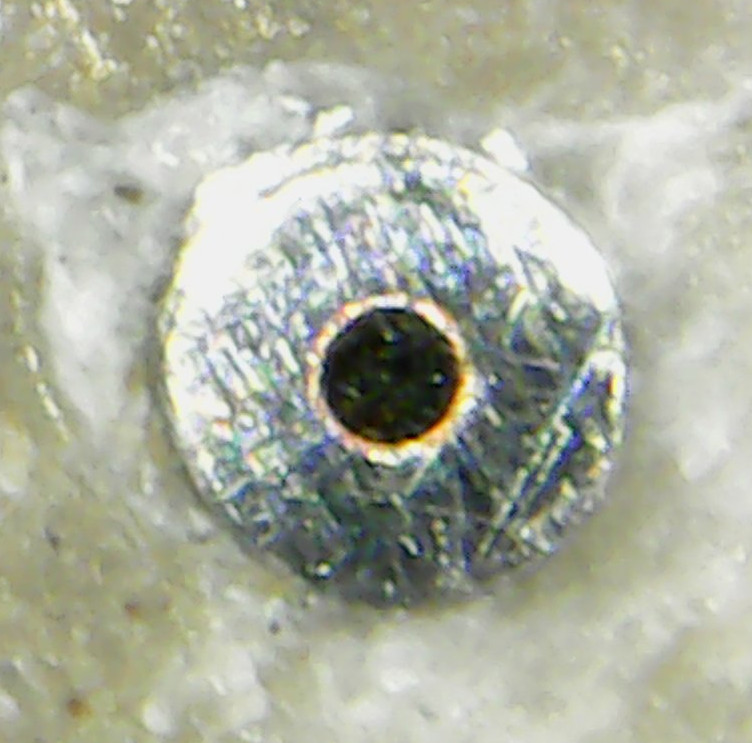

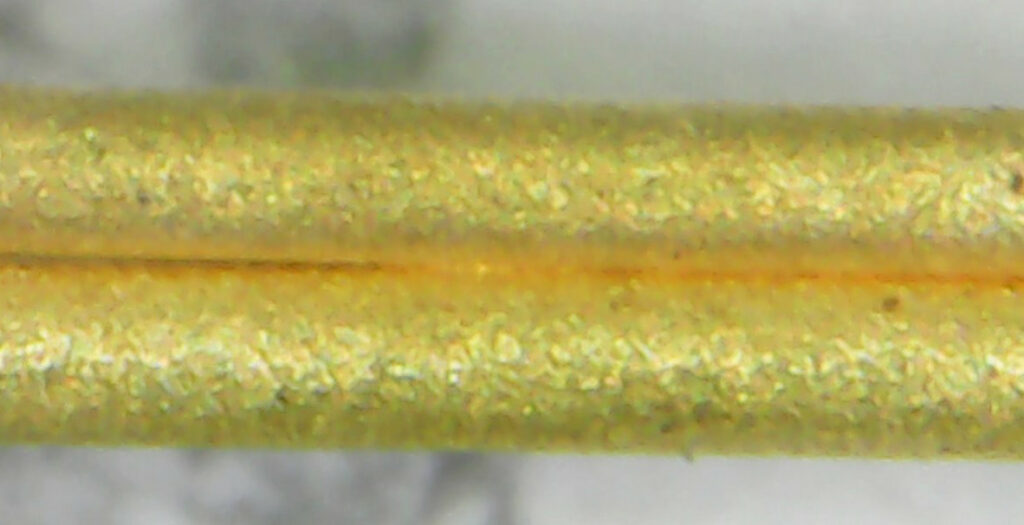

Similar test was performed with gold, picture of a gold coated optical fiber sample is placed below.

One can see 2 breakages of the glass fiber inside without any breakage of the metal coating.

It is well known that glasses which are annealed at high temperature for a long time are much more brittle that tempered glasses. The higher the cooling rate, the lower the brittlenes (L. Zheng et al., Structural Causes of Brittleness Changes in Aluminosilicate Glasses with Different Cooling Rates, Materials, 2024). Once we decide to perform a long term annealing, after some time the bending strength will deteriorate. The higher the temperature the shorter the time.

The pictures above may seem to present some extreme cases, but how about even a short term measurements? S.M. Popov et al. (Optical Loss of Metal Coated Optical Fibers at Temperatures up to 800°C, Optical Memory and Neural Networks (Information Optics), 2012) show that optical losses in copper coated optical fibers may increase over 10 times within 7 hours at 700°C.

If bending (and breaking) is the problem then is it possible to reduce it by placing the optical fiber in a tube? Not really as these optical fibers still will have the ability to move and deform inside the tubes. Please note that not just the silica glass undergo annealing during the process. Metallic copper and gold become super soft and ductile too.

Therefore one can solve this problem by replacing the soft metal coating with a hard metal coating, which would prevent the fiber from bending and breaking. Nickel fulfills such purpose. Even after a long term annealing it is much harder than copper without any heat treatment.

In ENDUROFIBER we can make a variety of nickel coated optical fibers for different applications.

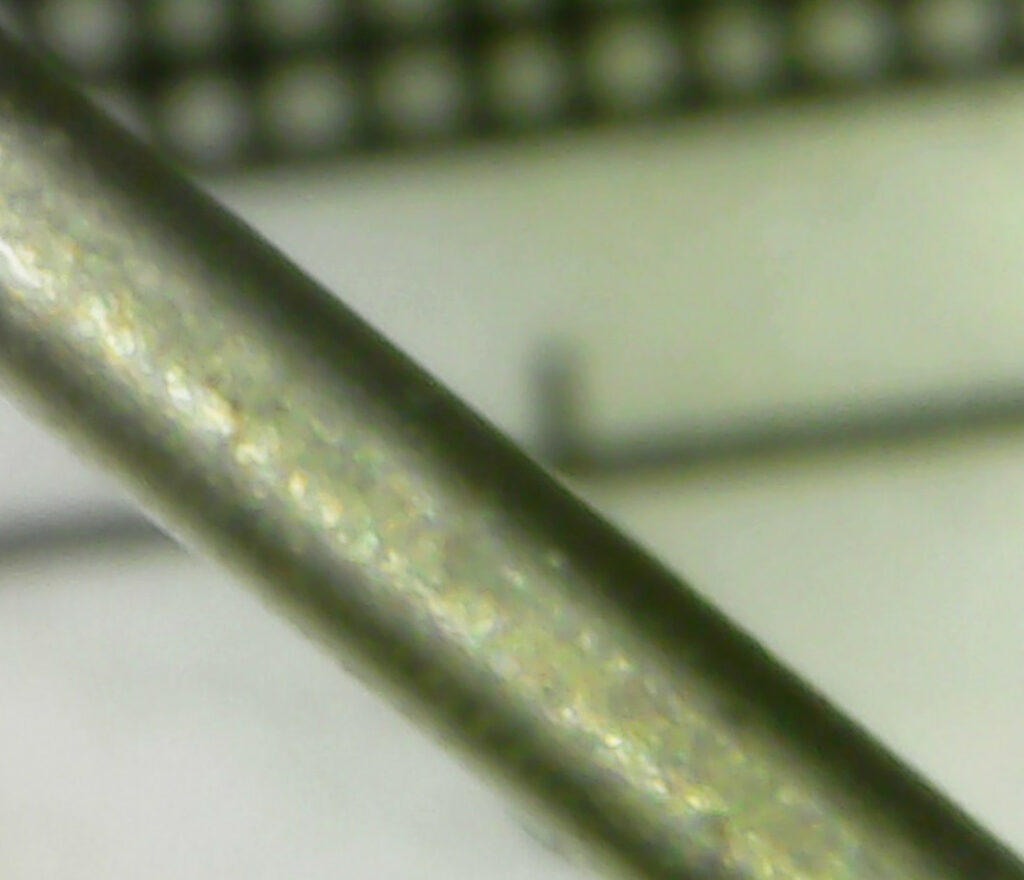

We can make thin coating for intermediate temperatures, like 500-600°C or very thick coatings (130 μm in total) for temperatures as high as 900°C.

Our nickel coated optical fibers have been proven to work properly with OFDR techniques for many months in industrial facility at high temperature. As a matter of fact they are still working.

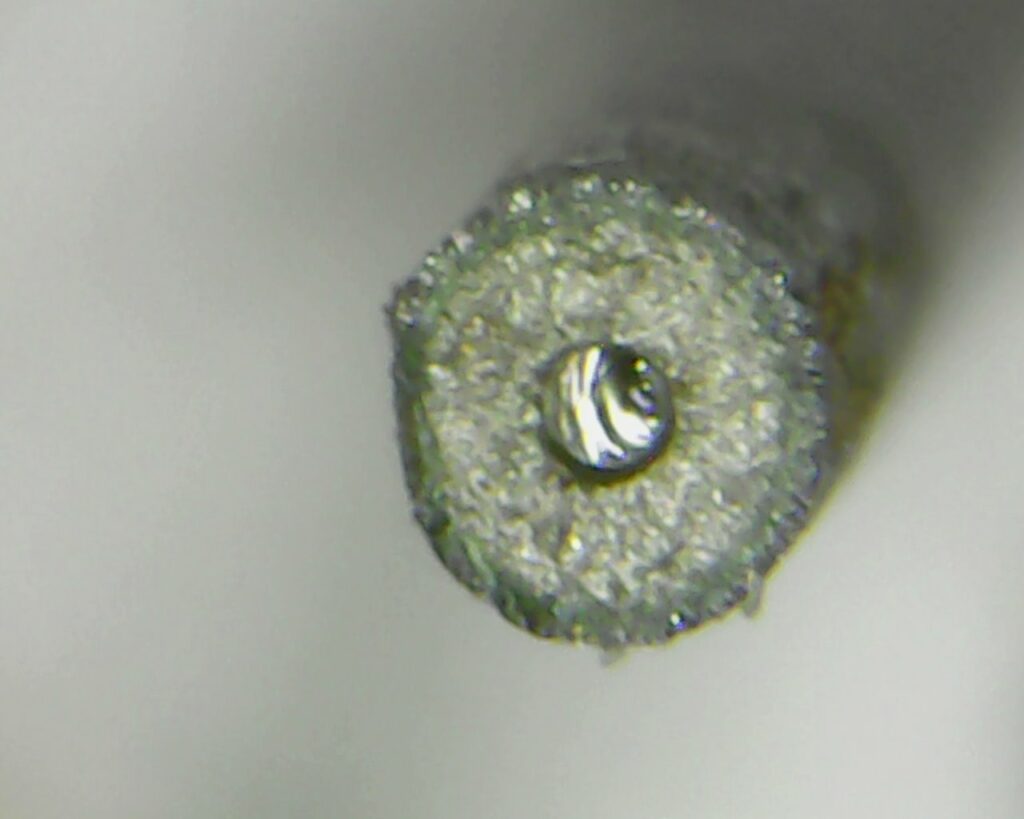

But does nickel oxidize? Yes, it oxidizes, but the oxide layer sticks to the surface of metal, which slows down the oxidation process. Oxide layer is thick and stiff and therefore may make bending more difficult, which is good for lifetime of metal coated optical fiber. Cross section of partially oxidized fiber is shown below. One can see how well the dark grey layer sticks to the inner green oxide layer and the latter to metal.

Are these all the advantages of nickel? Not at all. One should note that while gold is a quite soft metal at room temperature, it is very soft at high temperatures. The picture below shows a result of a following experiment. 2 gold coated silica optical fibers were twisted together and placed in a short tubular furnace (approximately 10 cm long, zone of the highest temperature was approximately 3 cm long), while outside the furnace there were end tips of the fiber available to grip. After reaching 700°C inside the furnace (measured with a thermocouple) each end was pulled away from the furnace. As a result two fibers spliced together so hard, that it was impossible to separate them without damage after removing them from the furnace.

This also proves why it is not recommended to let gold coated fibers touch other objects inside the furnace. Placing them in a metal tube would also lead to splicing of the coating to metal surface in some places, which would probably lead to deformations and breaking during temperature changes.

When is it then recommended to use gold coated optical fibers?

- Short fragments of optical fibers, which would not touch any other solid surfaces

- Optical fibers intended to use in aggressive environments at lower temperatures, e.g. 400°C

Dodaj komentarz